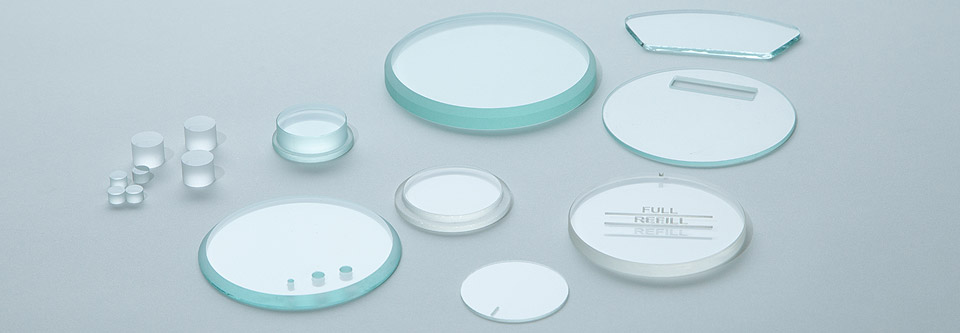

Precision CNC Glass Machining

Cat-i Glass is in the forefront of tight tolerance, high volume CNC glass processing. Cat-i engineers have developed many of the glass grinding techniques and machinery used throughout the industry.

Common Glass Machining Processes:

|

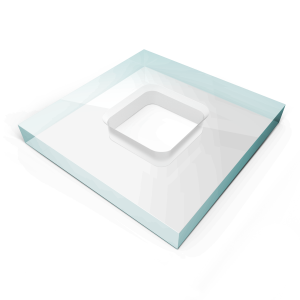

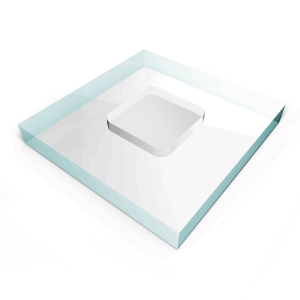

Step Routing |

Hole Drilling |

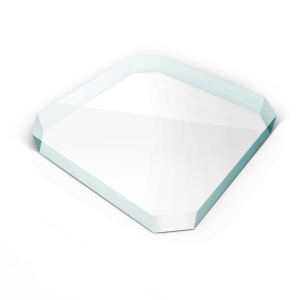

Beveling |

|

Internal Edge Profiling |

Corner Dubbing |

Blind Holes/Pockets/Slots |

|

Periphery Edge Profiling |

CNC Machining Advantages:

Possibilities

With CNC glass processing we can produce nearly any shape imaginable. We can use your CAD files or blueprints to generate machine toolpaths.

Quality

Our CNC machines are utilized with one thing in mind, producing quality glass products. They consistently hold tight tolerances over millions of parts and receive routine maintenance to make sure their performance never degrades.

Delivery

Our machines are designed to reduce set-up times and changeover required to process a wide variety of parts. We also develop equipment to simultaneously process multiple parts and some machines run around the clock. This means you can rely on Cat-i to consistently make delivery times and even expedite processing.

EDGEWORK

When a glass fabricator first cuts a piece of glass from a flat-glass sheet, the resulting piece invariably will have rough, sharp and unsafe edges. Cat-i Glass grinds and polishes these edges of these raw pieces to make them safer to handle, reduce chipping, improve structural integrity and enhance appearance.

HOW DO I DETERMINE WHAT TYPE OF EDGE IS BEST FOR MY GLASS PRODUCT?

The Cat-i Glass team consists of several experienced in-house glass fabrication engineers who are always willing to assist customers in selecting the right glass edging process for their products. An essential element of this process is to help the customer avoid any unnecessary costs.

Our equipment can shape a glass edge to any profile. Standard profiles include:

- Cut – A sharp edge is created when glass is scored and vented.

- Safety Seam – A safety seamed edge is a small chamfer that is safer to handle and less likely to chip.

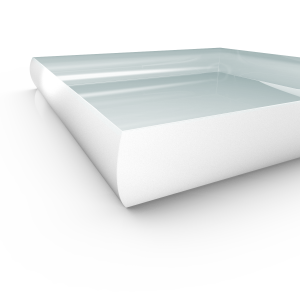

- Pencil – Pencil, also known as "C-shape", is a radius profile.

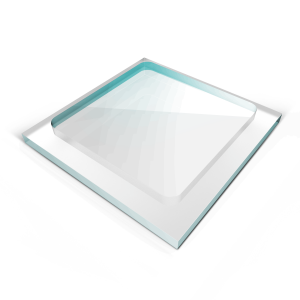

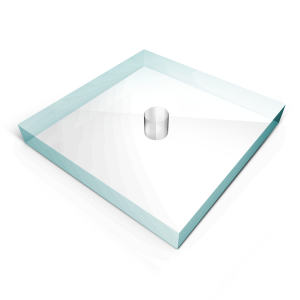

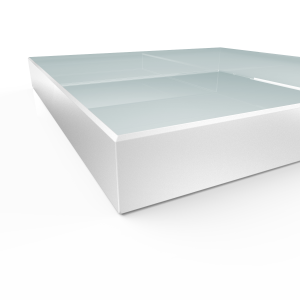

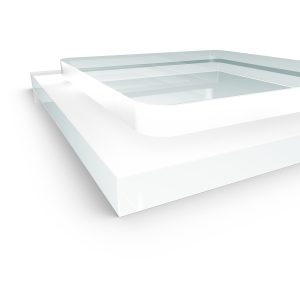

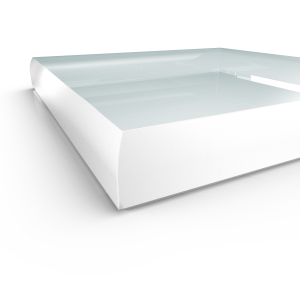

- Stepped – A step can be milled into the top surface creating a lip for mating the glass to your housing.

- Dubbed Corner – The corners off the glass pane are slightly flattened to reduce sharpness and injury.

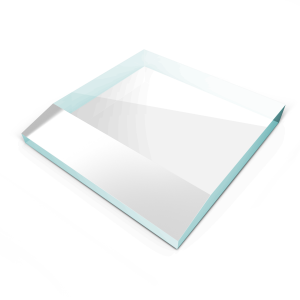

- Flat Ground – Edges are ground flat and edge corners are sharp.

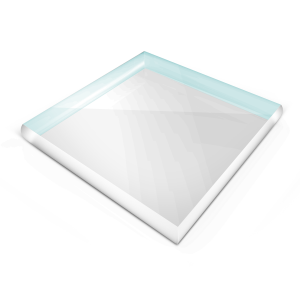

- Flat with Arris – Edges are ground flat and light bevels are added to every edge corner.

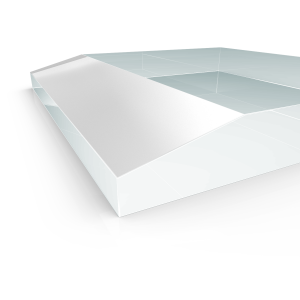

- Beveled – Additional edges may be put on the glass giving the piece additional faces. Angle and size of bevel is to your specification.

- Combined Profile – Some projects may require a combination of edgeworks; contact a member of the Cat-i Glass team for assistance.

|

Safety Seam |

Stepped |

Pencil Profile |

|

Flat with Arris |

Beveled |

Combination Profile |

Unrivaled Capabilities No matter the job, we can handle it

Cat-i Glass is a full-service flat-glass fabricator with in excess of 150 employees and more than 100,000 square feet of production area. Cat-i Glass is proud to offer the following capabilities: